Sheet metal rolling:

From a flat surface to a cylindrical part, our specialty

Our rolling know-how

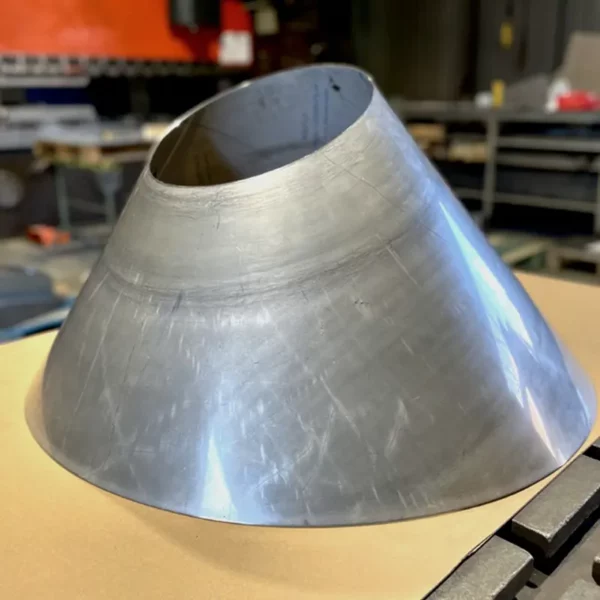

We stand out in the roll bending of long lengths of sheet metals of up to 3 meters and of specific materials. Our craftsmanship and know-how allows us to produce parts with non-standard diameters, whether they be cones, cylindrical parts or with complex shapes

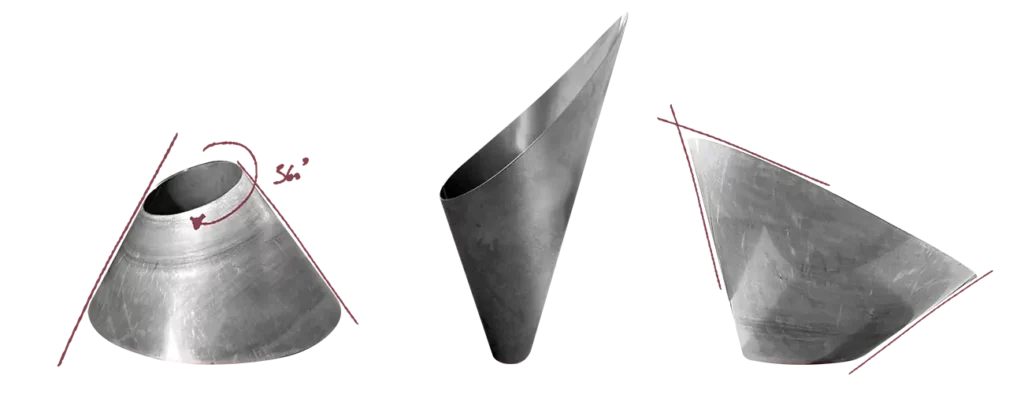

Rolling of

cones

We produce concentric parts that can be used for hoppers or for reducers or sometimes oblique or truncated tank bottoms, with or without step-bending.

Rolling of cylindrical parts

We form cylindrical parts of all dimensions, going from long, thin tubes to a ring or a thick spacer.

Rolling complex shapes

By combining roll bending, bending and step bending, we can make round, square, rectangular tubes or tubes with non geometric shapes, produced as a single part, with only one weld.

Craftsmanship in the service of industry

Specific tooling and a machine fleet of 18 rollformers

We rely on our internal machine fleet and numerous forming tools to produce cones, cylindrical parts and varied and complex shapes.

A team of experienced rollformers

The manual know-how of our team offers dexterity and sensitivity to the material that allows them to know where to fold or to straighten so as to fashion your most complex parts.

State-of-the-art

technology

Being a leader in this field, we are equipped with 2D and 3D modeling technology.

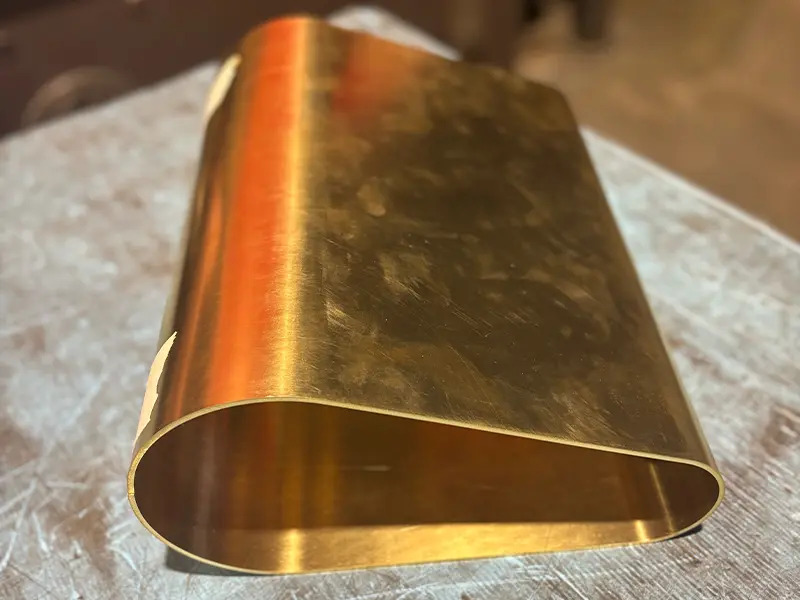

The materials worked

We work with all kinds of metals like steel, stainless steel, aluminum, copper, brass, nickel, titanium, Inconel and their alloys. We make cones with and without step-bending in perforated, mirror surface polished or brushed finished sheet metal.

Quality services

Our clients have confidence in us for the quality of our services. Especially thanks to the documentary organization established from the ISO 9001 and EN 9100 standards.

Our rollformed sheet metal productions

Single cone, small and medium production runs for cylindrical parts, prototypes or unique challenges

We are the subcontractor of reference for different metalworking factories and different assemblers for formed parts meeting your requirements.