Sheet metal bending :

the mastery of the detail

Our know-how in sheet-metal bending

The bending of long lengths and large thicknesses of sheet metal, whether of steel, aluminum or other materials, is at the core of our expertise. Our two metalworking workshops are specially equipped to adapt the bending to your project, your parts and your materials.

Folded parts

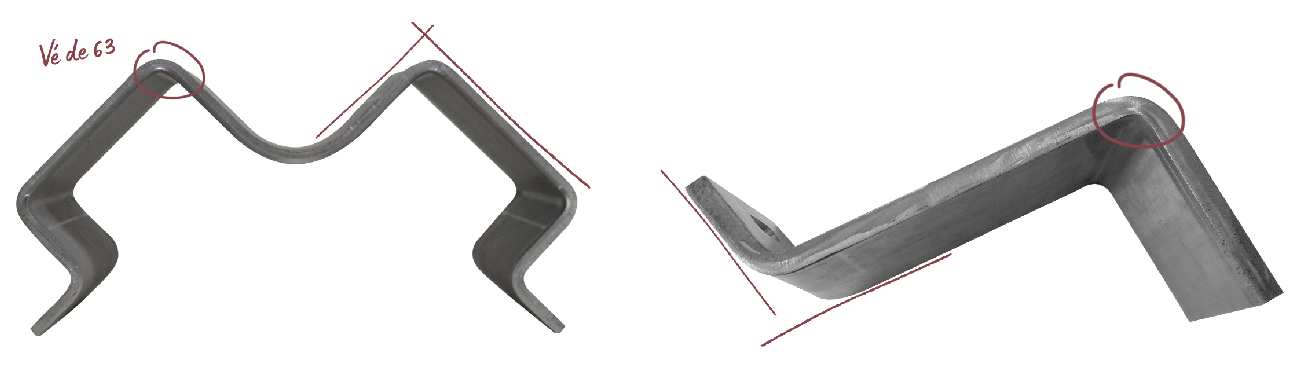

In order to fold a part, we always need a Vee + punch pair. Each thickness and each type of fold requires specific tools. Thanks to our set of diverse tools, we are able to meet a wide range of bending needs.

Complex parts

To fabricate complex parts by sheet metal bending, we rely on creativity and ingenuity so that the impossible can take shape! Our know-how is stimulated by your needs.

Craftsmanship in the service of industry

A bending machine and specific tools

We are equipped with an AMADA 400 tonne press, 4200 mm in length with a machine opening of 660 mm in addition to a large range of special tools able to fold both thick and thin sheet metal.

For a good

fold

The manual know-how of our team offers dexterity and a sensitivity to the material that allows it to know where to fold in order to fashion the most complex parts..

Without forgetting the technology

Being leaders in this field, we are equipped with 2D and 3D modeling technologies since 1999.

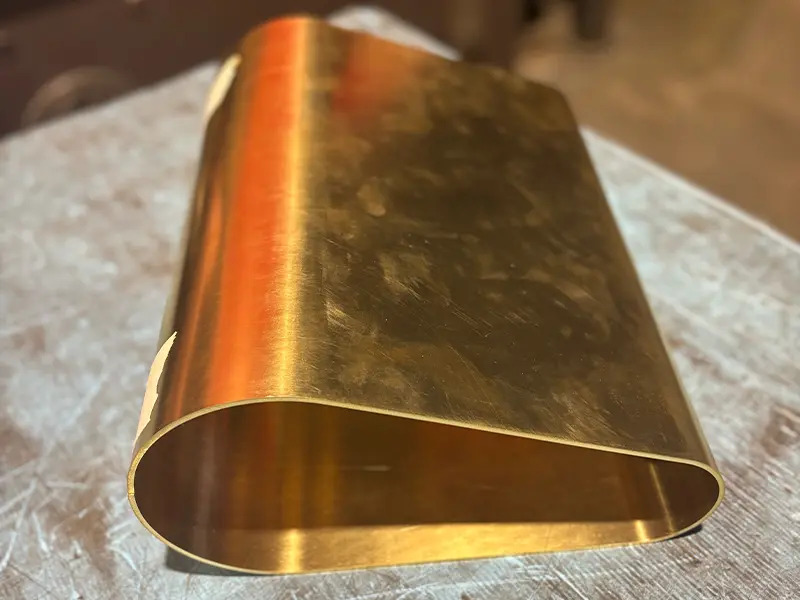

Materials folded

Although we do not keep a stock of raw materials, our know-how allows us to work with a wide range of materials: steel, stainless steel, aluminum, copper, brass, nickel, titanium, Inconel and their compounds.

Faultless fold quality

Quality is a strong commitment at Brilla. It is at the heart of our production process for the production of complex, folded parts.

Our folded sheet metal productions

Single parts, small and medium production runs or unique challenges

At Brilla, our technical process offers precision work in the production of folds with variable radii, from a single part or prototype to a small or medium production run.